The transfer of liquid gas is an essential process in various industries, including energy, transportation, and manufacturing. Understanding how liquid gas is transferred safely and efficiently is key to maintaining operations and ensuring the safety of both workers and the environment. Whether it’s liquefied natural gas (LNG), liquefied petroleum gas (LPG), or other types of liquid gases, the transfer process involves specialized equipment, procedures, and safety protocols.

Let’s take a closer look at how this transfer is conducted.

1. Transfer Methods

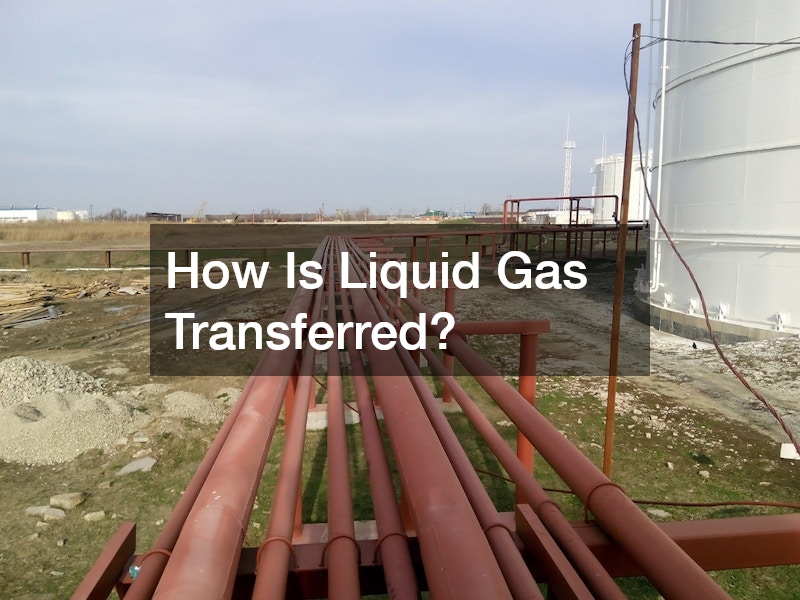

One of the most common methods for transferring liquid gas is through pipelines. Specially designed pipelines are used to move the gas in its liquid state from storage facilities to its intended destination, such as refineries or processing plants. These pipelines are heavily insulated to maintain the extremely low temperatures required to keep the gas in its liquid form.

For shorter distances or smaller quantities, trucks and railcars equipped with cryogenic tanks are used to transport liquid gas. These tanks are built to withstand the pressures and temperatures associated with liquid gas. Once at their destination, the liquid gas can be transferred to storage tanks or directly into distribution systems through pumps and hoses.

2. Maintaining Cryogenic Temperatures

Liquid gases are stored and transferred at very low temperatures to keep them in their liquid state. For instance, LNG is stored at temperatures of -162°C (-260°F). To maintain these cryogenic conditions during the transfer process, specialized insulated containers and pipes are used. The containers and equipment are designed to minimize heat transfer, ensuring that the liquid gas remains stable during transport.

3. Safety Measures

Because liquid gas is highly pressurized and extremely cold, safety is a top priority during transfer. Workers handling liquid gas must follow strict protocols, including wearing protective gear to guard against burns and frostbite. Facilities handling liquid gas transfers are equipped with safety systems that detect leaks, monitor pressure levels, and provide emergency shut-off mechanisms to prevent accidents.

In addition to personal safety, environmental safety is also critical. Any accidental release of liquid gas can lead to fires, explosions, or environmental damage. As a result, regular inspections and maintenance of equipment used in the transfer process are crucial.

4. Vaporization

Once the liquid gas has been transferred to its destination, it often needs to be vaporized before being used. This process involves heating the liquid gas to return it to its gaseous state, making it suitable for use in energy production, heating, or industrial processes. The vaporization process can be done using ambient air vaporizers or other heat exchange systems.

Understanding how liquid gas is transferred is essential for industries that rely on these products. With the right methods, equipment, and safety protocols in place, the transfer of liquid gas can be conducted efficiently and safely, ensuring smooth operations across various sectors.

.